Quality Assurance Activity

Inspection of incoming material and vendorized parts.

In-line inspection of radiator and spring.

Statistical process control

Continuous improvement to reduce rework and rejection of both the products.

Calibration of measuring equipments internally and externally.

Identify the non-conformities of the quality management system.

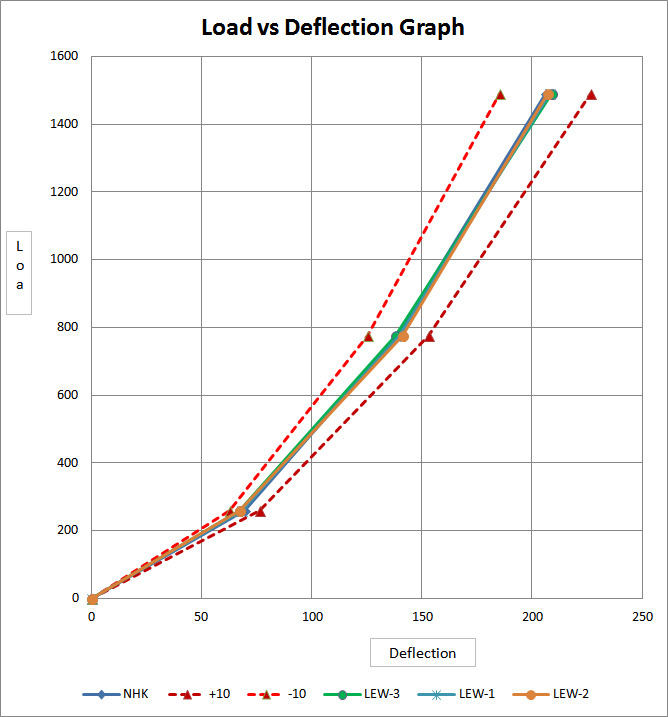

Testing of material e.g. tensile test, microstructure, decarburize depth.

Metallurgical Laboratory An Edge Over Industry

LEW has got state of the art Metallurgical Lab which is well on studying the physical and chemical properties of metallic elements and their alloys, which are combinations of different metallic elements.

Metallurgical lab at Lew supports clients from the automotive industry and for that purpose teams of industrial engineers and experts serve company in manufacturing products containing metal components.

Our plants work under strict Quality Assurance at different stages of Production. We have the skilled work force in our production lines, followed by qualified engineers.